Secure Delivery via Codesys Control

With two alternative Codesys control solutions including program porting, TURCK and Turck Mechatec are strengthening the crisis resilience of STS Brandschutzsysteme

When STS Brandschutzsysteme GmbH came under pressure due to supply bottlenecks for its HMI controllers, quick help was needed. The solution: flexible compact controllers from TURCK with Codesys – programmable independently of the manufacturer and combinable in a modular fashion. With support from in-house engineering service provider Turck Mechatec, the existing control program was ported in a very short time – including the user interface. This enabled STS to remain delivery-capable while building resilience through the manufacturer-independent control solution. The example shows how partnership-based cooperation and technological openness foster crisis resilience.

STS Brandschutzsysteme specializes in the planning, delivery, installation, and maintenance of customized fire protection systems for industrial machines and equipment. The solutions offered include fire extinguishing systems for filter and extraction systems, machines, wet paint and powder coating systems.

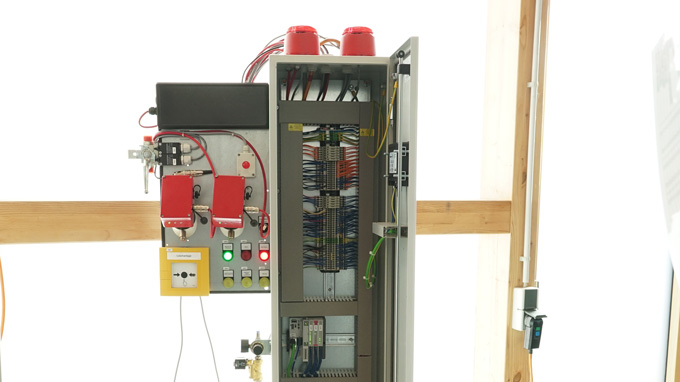

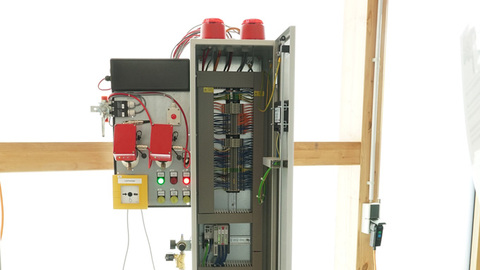

Structure of STS fire protection systems

Fire protection systems from STS typically consist of the following core components: sensors, more specifically UV or IR detectors for fire detection, and in some cases also temperature and smoke detectors. The signals from the sensors are evaluated by a control system, which initiates extinguishing or shutdown in an emergency. At STS, extinguishing is usually carried out by means of CO₂ injection or a flame barrier is set up using CO₂ or a mechanical barrier. Communication between the sensors, actuators, and control system is carried out exclusively via hardware contacts – without protocols.

Component shortage puts STS Brandschutz under pressure

When electronic components became difficult to obtain in 2021, STS was also unable to use its control systems with the usual delivery performance. Managing partner Reinhard Deseife and his team had to come up with something. The company purchases control systems and other electronic equipment from electrical and automation technology wholesaler Emil Löffelhardt.

Interim solution quickly sold out

It's like at the supermarket checkout: when a new checkout opens and too many customers respond to the call, you can quickly find yourself waiting longer at the new checkout. Something similar happened to STS Brandschutz and the company Emil Löffelhardt. The first alternative solution with a compact control system from another manufacturer, which Löffelhardt suggested, did not last long. Although STS had delivered several hundred systems with the alternative control system , many other manufacturers behaved in a similar manner, and stocks of the alternative control system quickly ran out.

Two control solutions with Codesys

TURCK put together two alternative solutions for STS: one with HMI and BL20 I/O system with integrated controller, and alternatively a solution in which the controller is integrated in the HMI and a BL20 with pure I/O function is connected. The appeal of these solutions is that if there are delivery problems with one component, the alternative combination of HMI and I/O system can still be selected.

Turck Mechatec ports control program under time pressure

With the support of TURCK's engineering service provider Mechatec, TURCK and, in this case, wholesaler Emil Löffelhardt were able to offer the porting of the control program from the old system to the Codesys control environment. This was possible because Turck Mechatec has decades of experience with Codesys and has experienced programmers on its team who have worked with numerous PLC systems.

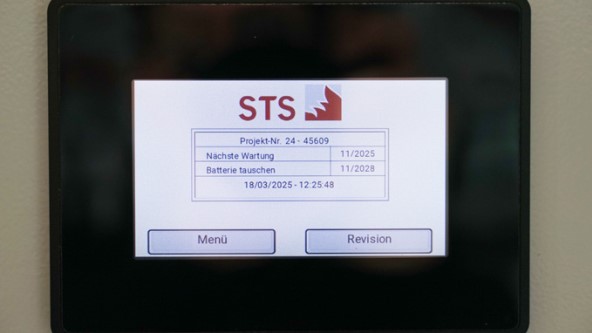

The Mechatec specialists worked closely with Markus Gutsch and his colleagues and were thus able to present a solution very quickly. The implementation of the graphical user interface also went smoothly. The customer will probably hardly notice any difference between the fire protection systems with the old control system and those with TURCK HMI.

- Technologies

- Asset Monitoring Gateway with Cloud ID

- Asset Monitoring Gateway with SNAP ID

- Codesys

- Condition Monitoring

- Ethernet in Hazardous Locations

- Field Logic Controller

- Industrial Cloud

- Industry 4.0

- IO-Link

- Machine Safety

- Modular Machines

- Module Type Package

- Multiprotocol Ethernet

- Pick-to-Light

- Profinet

- RFID

- Snap Signal

- Sustainability

- TAS – IIoT Service Platform

- The Visual Factory

-turck-image.jpg)

-turck-image.jpg)

-turck-thumbnail.jpg)

-turck-thumbnail.jpg)