Applications

Digital Packaging Sorting with RFID

CIRCPACK by Veolia and TURCK use RFID technology to make the sortability of packaging measurable – and provide manufacturers with valuable data for sustainable packaging development

RFID Solution for Data Acquisition in Stator Production

Chinese electric motor manufacturer ensures quality and traceability of stator production by using Turck's RFID system to track the workpiece carriers

Checking Hose Connections with RFID

B. Braun Medical AG guarantees reliable mixing and filling processes through fail-safe verification of hose connections in ATEX zone 2 – with an RFID solution from Turck

Reliable RFID Access Control for Inspection Robots

At the BASF plant in Antwerp, a four-legged inspection robot ensures the safety of the water treatment plant – and Turck's RFID solution ensures its reliable access to the charging station

ROI After Three Avoided Delivery Errors

For a plastic pipe manufacturer, the RFID solution for the comprehensive control of loading and delivery processes pays off after just three delivery errors are avoided

Sustainable Tracking of RTIs thanks to RFID

Logistics services provider Recalo monitors its pool of returnable transport items (RTI) with a track and trace solution from Turck Vilant Systems and thus reduces its customers' CO2 footprint

RFID System Identifies Solar Cell Carriers

Chinese solar cell manufacturer uses Turck's RFID system to increase the quality and efficiency of its production

RFID Solution for Error-Proof Material Logistics

KEB Automation is expanding its automated driverless transport system with RFID technology into a fully automated and fail-safe material logistics solution

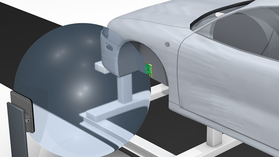

Modular Plant for Flexible and Efficient Production

Smart Automation developed a modular production line with decentralized control for an automotive supplier – from sensors to multiprotocol I/O modules, pre-assembled connection technology, LED lights right through to RFID

RFID Tracking of Battery Raw Materials with OPC UA

RFID system from a single source guarantees reliable processes – even with high throughput and complex and varying processes

RFID Solution with Smart Forklifts in Autombile Production

RFID solution with smart forklifts and IT integration via middleware from Turck Vilant Systems ensures reliable and fast goods flows in Chinese automotive plant

RFID Enables Unmanned Store at Major Building Site

Using an RFID system solution from Turck Vilant Systems, wholesaler chain ProMart developed the “EasyMart” shop concept – self-service containers or store rooms that make fixing materials and tools available at any time and on any site

Tracking Big Bags with RFID

Extensive control over the production and delivery process of assets as well as full compliance with legal requirements

Shipment Tracking for Raw Materials

Material transparency called for Sandvik to introduce an automated inbound processes with RFID

RFID-Based Tracking Solution for Loading Error Minimization

Jysk ensures delivery accuracy by fully automated tracking of position and direction movement of outgoing pallets

Error-free JIS Order Picking for Bumpers

UHF RFID tracking beyond trade and company boundaries ensures batch size one for automotive suppliers and OEMs

RFID-based Tracking of Inbound and Outbound Materials

ABB realizes 60 percent productivity growth by digitalizing their production including material flow tracking with an UHF-RFID system directly linked to the company’s SAP

RFID Bus Mode Ensures Quality of Lithium-Ion Batteries

Bus mode combines a high data transfer rate with a low cost per read position

Selective Asparagus Harvester

AvL Motion is breaking new ground – with a machine for the selective harvesting of white asparagus, 'garnished' with high precision sensors as well as RFID and fieldbus technology from Turck

RFID System Increases Efficiency in Copper Pipe Production

A Chinese manufacturer monitors the production process for copper pipes with a Turck RFID system with decentralized control using BL20 gateways

Fast Tag Detection at Warehouse Gates

Multiplex operation with external antennas on RFID UHF read/write head Q300

Decentralized monitoring of cooling stations

RFID system and decentralized logic guarantee high production quality of cable harnesses

Identification of Chocolate Moulds

With the help of the RFID-technology chocolate moulds are able to control their individual chocolate production process.

- Technologies

- Asset Monitoring Gateway with Cloud ID

- Asset Monitoring Gateway with SNAP ID

- Codesys

- Condition Monitoring

- Ethernet in Hazardous Locations

- Field Logic Controller

- Industrial Cloud

- Industry 4.0

- IO-Link

- Machine Safety

- Modular Machines

- Module Type Package

- Multiprotocol Ethernet

- Pick-to-Light

- Profinet

- RFID

- Snap Signal

- Sustainability

- TAS – IIoT Service Platform

- The Visual Factory

_rdax_280x157p.jpg)