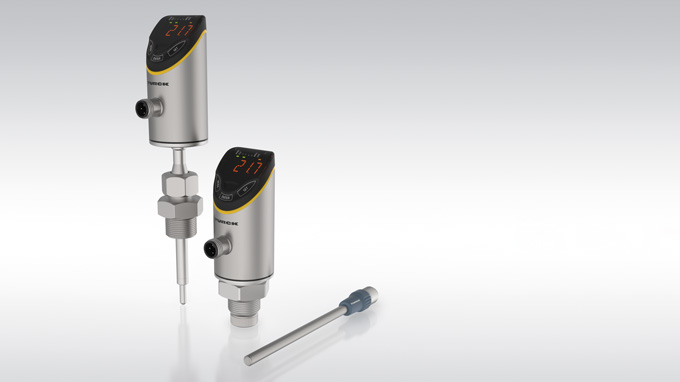

The TS+ is operated via capacitive touchpads and shows values on a 14-segment display

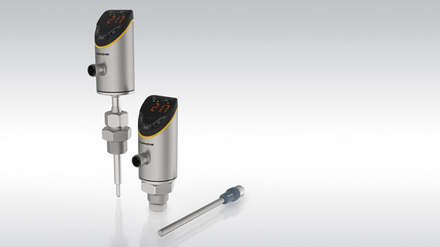

Temperature Sensors with Plug & Play

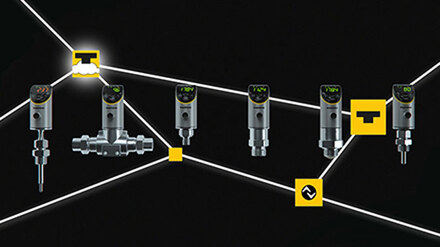

Turck's robust TS+ sensors with IO-Link offer smart functions for easy commissioning and predictive maintenance concepts

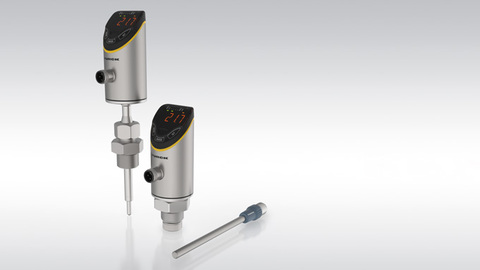

Turck is expanding its innovative range of fluid sensors with IO-Link-capable sensors for flexible and reliable process temperature measurement. Both compact devices with an integrated temperature probe (TS700) as well as processing and display units (TS720) for connecting resistance thermometers or thermocouples are available.

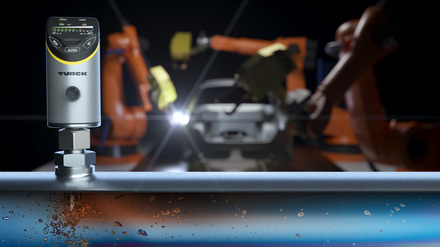

Robust sensor design with IP69K protection increases system availability

As a member of the fluid sensor series that won the iF Design Award, the TS+ sensors also meet the growing demand for straightforward commissioning and high plant availability. This is supported by the robust stainless steel housing with touch operation instead of mechanical operating elements, which are ideally suited for use in harsh industrial environments thanks to IP67 and IP69K protection. Besides process values, the IO-Link interface provides the user with a large volume of condition monitoring data for smart IIoT applications.

Your Benefits

- Simplified commissioning: Multiple process connections, powerful auto detection functions and adaptive IO-Link data mapping

- High system availability: Robust sensor design and condition monitoring data via IO-Link

- Intuitive operation: Interface with capacitive touchpads and two-color 14-segment display

- Immense freedom: Different measuring ranges and designs, almost all typical industrial probes can be connected

Auto detection for fast commissioning

To simplify commissioning, the TS+ devices also feature automatic detection of the output type (PNP/NPN or current/voltage), as is already offered by the PS+ and FS+ pressure and flow sensors. The processing units of the TS720 series also detect the type of temperature probe (TC or Pt), thus eliminating a frequent source of errors. If the TS+ has to be integrated in existing installations or replace existing sensors, the selection of different IO-Link process data profiles makes it possible to adapt the device quickly without the need for laborious modifications in the controller.

Two sensor variants with large measuring ranges

The TS+ sensors are typically used in machine and plant building applications as well as in the process industry. Compact TS700 devices operate in a measuring range from -50 to +150 °C. Depending on the temperature probe connected, type TS720 processing and display units can even cover temperature ranges between -200 and 1800 °C.

INDUSTRIES

- Machine and plant construction — e.g. temperature measurement on hydraulic aggregates

- Process industry — e.g. temperature measurement on dispensing heads

KEY FUNTIONS

- IO-Link 1.1

- Auto detection: switching output, analog output and type of temperature sensor

- Variable IO-Link process data mapping

- Adaptive menu structure: Turck or VDMA standard

- Protection classes IP67 and IP69K

- Capacitive touchpads

RELATED CONTENT

At a Glance: Fluid Sensors from a Single Source

Probably the best fluid sensor family for pressure, temperature, flow and level

Fluid Series: LS+ Ultrasonic Level Sensors

More about ultrasonic level sensors for high demands on flexibility, reliability and intelligent communication

Fluid Series: FS+ Flow Sensors

More about IO-Link flow sensors with Quick-Teach and Delta-Flow monitoring

Fluid Series: PS+ Pressure Sensors

More about robust pressure sensors for high demands on flexibility, reliability and intelligent communication

Article: Generation Plus

To learn more about the versatile fluid sensor portfolio with a standard platform concept, please read the technical article

PRODUCT DATA

All Details About the TS+

Approvals, data sheets, technical specifications, instructions, certificates, CAD data and more