World premier: Turck's new sensor series reliably detects all Carbon fiber reinforced polymer materials

Inductive Sensors for CFRP Detection

Turck has added the world's first inductive sensors for detecting Carbon fiber reinforced polymer to its portfolio

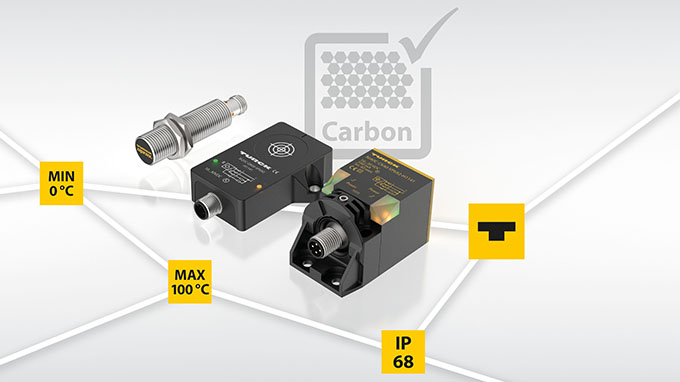

Turck has developed the world's first inductive sensors for detecting carbon fibers. The patent pending sensor series detects both carbon fibers as well as pressed CFRP parts. It is based on uprox technology that has been further developed and therefore offers very large switching distances as well as maximum mounting flexibility – such as is needed for manufacturers of automobiles, wind turbines or sports equipment and their suppliers.

Your Benefits

- High reliability thanks to IP68 protection and extended temperature range

- Large switching distance and different designs allow flexible installation

- More insensitive than optical or capacitive sensors

- Cheaper than ultrasonic sensors

Advantages over optical, capacitive and ultrasonic sensors

Compared to the previously used solutions in this area, the new sensors offer the following benefits: As optical or capacitive sensors, they are firstly more insensitive to contamination than optical or capacitive sensors, and secondly are considerably cheaper than ultrasonic sensors.

Variants in rectangular or threaded-barrel design

The sensors are available now in three designs: as a threaded-barrel design in an M18 stainless steel housing as well as a 20 mm (QR20) or 40 mm (CK40) high rectangular variant. Protection type IP68 and an extended temperature range of 0 to 100 °C guarantee permanently reliable use of the devices, which Turck offers as PNP changeover contacts with an M12 connector.

Flyer: Carbon Fiber Detection Sensors

Get an overview of our range of inductive safety sensors for CFRP detection

PRODUCT DATA

All Details about the BI7C-EM18, NI40C-CK40 and BI20C-QR20

Approvals, data sheets, technical specifications, instructions, certificates, CAD data and more